The cost of inventory at the end of an accounting period is determined by absorption costing. The closing inventory also includes fixed costs, which raises the inventory’s value. However, its limitations, such as absorption costing the risk of overproduction and challenges in overhead allocation, necessitate careful interpretation and complementary use of other costing methods like variable costing. As businesses embrace technological advancements, absorption costing is becoming increasingly efficient, enabling companies to make informed decisions in a competitive market. Understanding and effectively applying absorption costing principles can help businesses achieve long-term financial stability and success.

Absorption Costing Complete Details: Meaning, Types & Formula

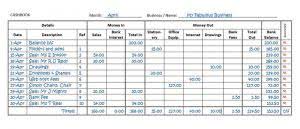

Finally, the costs are computed by allocating the cost pools to the products based on usage. This involves dividing the total cost of each pool by the total usage to get a price per resource unit, which is then multiplied by the amount used by each product. This step ensures that each product absorbs a fair share of the total manufacturing costs. Both the above methods are accounting techniques that companies use to allocate the cost of production over the total number of units produced. Fixed manufacturing overhead costs remain constant regardless of the level of production. These include expenses like rent for the manufacturing facility, depreciation on machinery, and salaries of supervisors.

Formula

The absorption costing method provides for reporting a high profit with a high value of closing inventory. This is because Insurance Accounting the production cost has been completely absorbed in this costing approach. Absorption costing and variable costing are two distinct methods used to determine product costs, and they treat fixed overhead costs differently. Companies in the electronics industry use it to determine the cost of manufacturing electronic devices, such as televisions, cameras, and audio equipment.

The largest global training provider.

StudySmarter’s content is not only expert-verified but also regularly updated to ensure accuracy and relevance. Absorption Costing is an advantage for companies with constant product demand. It lays out a simple and systematic costing tool for active businesses while considering fluctuating turnover, as costs are contribution margin already fixed for the products.

- As businesses embrace technological advancements, absorption costing is becoming increasingly efficient, enabling companies to make informed decisions in a competitive market.

- Finally, Absorption Costing provides a comprehensive approach to cost accounting by including all manufacturing costs.

- By applying this formula, a business ensures that each unit of product reflects its share of all incurred costs.

- These costs are also known as overhead expenses and include things like utilities, rent, and insurance.

- Absorption or “full costing” is an accounting process designed to capture all the costs of making a specific product.

Determine Cost Usage

Absorption costing is also often used for internal decision-making purposes, such as determining the selling price of a product or deciding whether to continue producing a particular product. Fixed manufacturing overhead comprises expenses that remain constant regardless of production levels, including rent, salaries of permanent staff, and insurance. The various manufacturing or production costs related directly to the produced goods or other cost objects are what we refer to as overheads.

- Absorption costs will become $7 per unit ($5 for labor and materials plus $2 for fixed overhead costs).

- Absorption costing remains a vital tool for businesses seeking a complete understanding of their production costs.

- It’s particularly beneficial for long-term decision-making and pricing strategies.

- Direct materials are the raw materials that can be directly attributed to the production of a specific product.

Absorption costing can lead to inflated profits if inventory levels rise and may encourage overproduction to lower per-unit costs. Additionally, allocating fixed costs accurately across diverse products can be complex. For instance, if a company is deciding whether to discontinue a product, variable costing allows management to focus solely on the costs directly impacted by the decision. Absorption costing, in contrast, might allocate fixed costs to the product, complicating the analysis and potentially leading to inaccurate conclusions. On the other hand, period costs are not directly related to production as they are accumulated over a set period.